Cov khoom

Perforated steel sawb PE yeeb nkab Rau cua sov

Daim ntawv thov

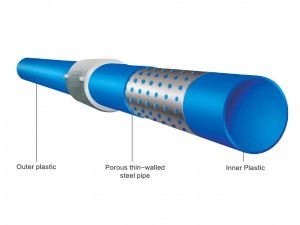

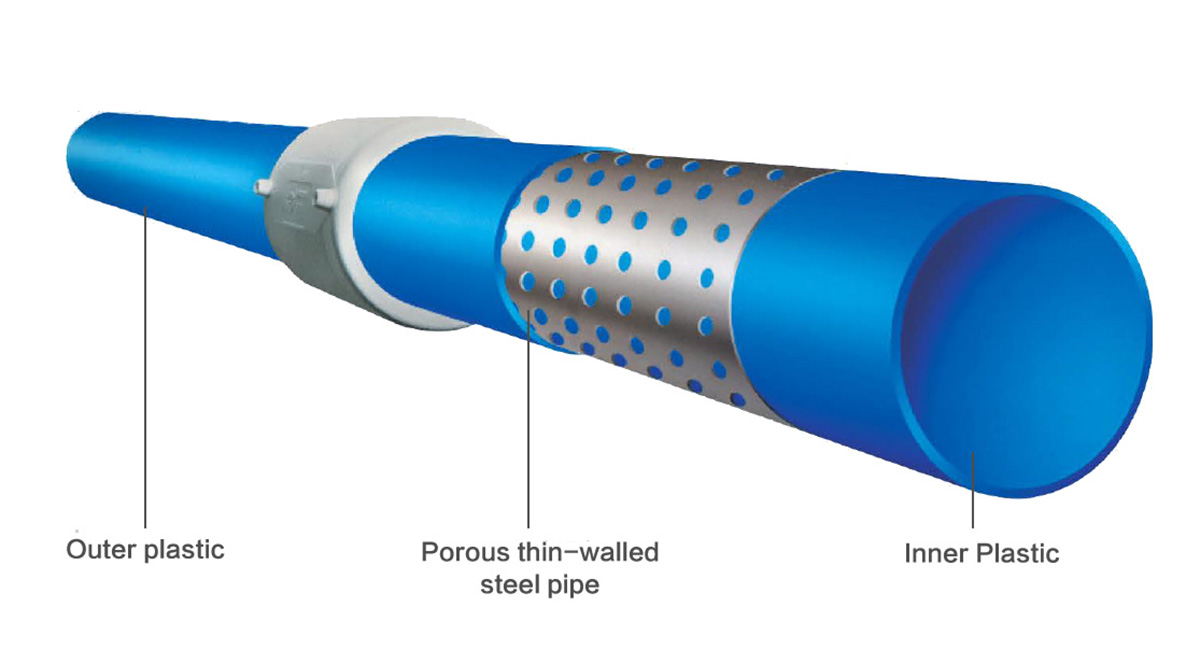

Perforated steel strip polyethylene composite yeeb nkab yog ua los ntawm txias-dov strip steel thiab thermoplastics raws li raw cov ntaub ntawv, thiab ntxeem tau nyias-walled steel kav tsim los ntawm argon arc taub qab vuam los yog plasma kauv vuam yog siv los ua reinforcements. Cov txheej txheej sab nrauv thiab sab hauv yog ob sab sib xyaw thermoplastics. Ib hom tshiab ntawm cov yeeb nkab siab, Vim tias qhov ntxeem tau nyias-walled steel yeeb nkab reinforcement yog qhwv hauv cov thermoplastic tsis tu ncua, cov yeeb nkab sib xyaw no tsis tsuas yog kov yeej cov kev ua tsis zoo ntawm cov kav hlau thiab cov kav dej yas, tab sis kuj muaj cov rigidity ntawm cov kav hlau thiab cov corrosion. tsis kam ntawm cov kav dej yas. Nws yog kev daws teeb meem rau roj av thiab tshuaj lom neeg kev lag luam. Nws yog ib qho kev xav tau ceev ceev ntawm cov kav dej loj thiab nruab nrab txoj kab uas hla hauv cov chaw muag tshuaj, khoom noj, mining, roj thiab lwm yam kev lag luam. Nws kuj yog ib qho kev hloov kho thev naus laus zis los daws cov kav dej loj ntawm kev tsim kho thiab hauv nroog dej. Nws yog ib hom tshiab ntawm cov kav dej sib txuas hauv 21stxyoo pua.

Nta

High rings nruj thiab siab rigidity

Lub perforated steel strip yas composite yeeb nkab muaj lub nplhaib siab nruj thiab siab rigidity ze rau cov kav hlau hlau, thiab tshwj xeeb tshaj yog tsim rau cov nyiaj siv ua haujlwm ntawm cov yeeb nkab txoj kev hauv tsev.

Kev nyab xeeb kev ua haujlwm

Lub zog thav duab ntawm perforated steel siv cov yas sib xyaw yeeb nkab thiab cov ntaub ntawv yas raw khoom muaj tag nrho los ntawm cov net perforated, thiab muaj kev txhawj xeeb ntawm tev tawm ntawm sab hauv thiab sab nrauv phab ntsa yas thiab steel ncej. Kev sib txuas hluav taws xob fusion muaj zog tiv thaiv kev kos duab axial, thiab cov kav dej muaj kev ntseeg siab. Raws li ib txwm muaj, lub neej kev pabcuam tuaj yeem ncav cuag 50 xyoo.

Technical Parameters

| Nominal sab nraud txoj kab uas hla thiab sib txawv | Nominal phab ntsa thickness thiab sib txawv | Nominal siab | Yam tsawg kawg S tus nqi |

| Dn (mm) | En(mm) | Mpa | Mm |

| 50 + 0.5 0 | 6.0+1.5 9 | 2.0 | 1.5 |

| 63+0.6 0 | 6.5 + 1.5 0 | 2.0 | 1.5 |

| 75+0.7 0 | 7.0 + 1.5 0 | 2.0 | 1.5 |

| 90 + 0.9 0 | 8.0 + 1.5 0 | 2.0 | 1.5 |

| 110 + 1.0 0 | 9.0 + 1.5 0 | 2.0 | 1.5 |

| 140 + 1.1 0 | 9.0 + 1.5 0 | 1.6 | 2.0 |

| 160 + 1.2 0 | 10.0 + 1.8 0 | 1.6 | 2.0 |

| 200 + 1.3 0 | 11.0 + 2.0 0 | 1.6 | 2.0 |

| 225+1.4 0 | 11.5+ 2.2 0 | 1.6 | 2.0 |

| 250 + 1.4 0 | 12.0 + 2.2 0 | 1.6 | 2.0 |

| 280+ 1.5 0 | 12.5+ 2.3 0 | 1.6 | 2.5 |

| 315+1.5 0 | 13.0 + 2.5 0 Nws | 1.25 | 2.5 |

| 355+1.6 0 | 14.0 + 2.5 0 | 1.25 | 2.5 |

| 400 + 1.6 0 | 15.0 + 2.8 0 | 1.25 | 2.5 |

| 450+1.8 0 | 15.0 + 2.8 0 | 1.25 | 2.5 |

| 500 + 2.0 0 | 16.0 + 3.0 0 | 1.25 | 2.5 |

| Lub cev muaj zog ntawm cov yeeb nkab sib xyaw | ||

| Qhov project | Kev ua tau zoo xav tau | |

| Cracking stability nyob rau hauv siab | Tsis muaj kab nrib pleb | |

| Longitudinal shrinkage tus nqi (110 ° C, tuav 1h) | <0.3% | |

| Hydraulic xeem | Kub: 20 ° C; Sijhawm: 1h; Siab: nominal siab x1.5 | Tsis tawg Tsis muaj dej paug |

| Kub: 70 ° C; Sijhawm: 165h; Siab: Nominal siab x1.5x0.76 | ||

| Kub: 85 ° C; Sijhawm: 165h; Kev tawg siab ≥ nominal siab x1.5x0.66 | ||